Benefits of Reshoring to Midwest Manufacturing

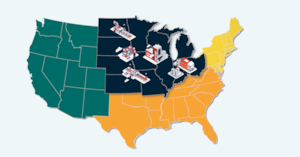

For decades, the slogans 'Made in USA' and 'Made in China' have raged a ferocious battle. Today, of course, US manufacturers aren’t just competing with China. Large midwestern cities that once ruled the manufacturing world collectively became known as 'the rust belt', because so many manufacturers have opted for off-shoring production rather than the costlier option of domestic production. In recent years, midwestern cities have experienced some positive growth in the manufacturing sector. While it's not a return to glory (yet), it has companies re-examining the actual benefits of reshoring.

Benefit #1: Money - Profits & Losses

The chief reason that domestic manufacturing suffered in the latter half of the 20th century is all about the money. Overseas companies could produce products at a price point, and American companies could not compete. Many manufacturers determined that if they couldn't beat these overseas competitors, they'd join them--or, rather, move their location where they could produce products using the same cheaper labor source.

That's still largely true. Americans make more for producing the same products than Chinese laborers, for instance. However, cost savings are adding up and encouraging some companies to return to midwest manufacturing. For instance, overseas supply chain interruptions have potential to sink profits. One of the reasons Mursix, a midwest manufacturing company, has been able to remain successful during the pandemic is because it was able to safeguard its supply chain and shift gears to meet consumer demand for face shields.

Benefit #2: Technology

While developing nations may have cheap labor, they don't have the same technological resources that many U.S. manufacturers do. In the Midwest, for instance, Mursix already had the technology on board it needed to produce those mentioned face shields--even though it had not produced these products before. Midwestern manufacturing companies who have been able to invest in tech solutions have also been able to adapt well to change, like this current pandemic.

Benefit #3: Supply Chain

Another benefit that a domestic company has over their offshoring competitors is the ability to get midwest manufacturing products to the American marketplace--still the most lucrative market--more quickly.

Because of the seamless integration of technology, that speed is even greater than, perhaps, it was decades ago. Couple that with a secure supply chain, and the speed at which companies can move products often dwarfs the overseas competition.

With these benefits in mind, it's no surprise that off-shoring businesses are considering reshoring. Even during the pandemic, midwestern component manufacturers, like Mursix, are safeguarding manufacturing jobs in the midwest and new innovations. If the trend continues, rust belt cities may be gleaming again.

More About Mursix Corporation

Mursix, a midwest precision components manufacturer, has been delivering custom-engineered product solutions and precision components to our customers since 1945. We began providing the appliance industry with timer and motor components, and grew to serve the automotive industry with metal stamping and wire harness assemblies. Our capabilities have grown to also include CNC machining, injection molding, welding, plating, and value added services. We are now known for our engineering and development process. Especially helpful in the home automation, medical, alternative energy, and lighting industries, this service helps to provide solutions throughout the product development lifecycle, from engineering to design to manufacturing and assembly.